About the GDS digester

Description

The GDS Digester is a state-of-the-art, fully enclosed system designed to convert deceased livestock waste into high-quality bone and meat meal within just 20 hours. By utilizing advanced thermophilic enzyme technology, the GDS Digester efficiently breaks down organic waste through rapid and effective fermentation. Depending on the drying materials used, the resulting output can be effectively used in aquaculture farming (rice husks, coconut husk) or as organic fertilizer (saw dust).

How it Works

GDS digester uses the principles of “mechanical crushing + biological fermentation + high-temperature sterilization” to address the challenges of processing deceased ruminants and other animal organic waste.

High-Temperature Sterilization: The processing tank operates at 120°C to 160°C, raising material temperature to nearly 100°C in 3 hours, effectively eliminating pathogens. Similar equipment on the market typically operates at around 120°C, with material temperatures controlled at about 80°C. Our superior processing temperatures enhance the reproduction of high-temperature-resistant Greenzyme EMB-100 Plus, speeding up organic matter decomposition, and drying the treated products for easier storage or reuse.

Mechanical Processing: Rotating blades cut and crush the carcasses, increasing surface area and mixing for better fermentation and decomposition, including grinding bones for thorough treatment.

Biological Fermentation: Utilizing the high-temperature-resistant bacteria Greenzyme EMB-100 Plus, combined with water, oxygen, and heat, to rapidly decompose organic waste. Additives like sawdust and bran enhance absorption and fermentation.

Traditional Deceased Livestock Treatment Methods

Burial Method:

- High cost. Pollutes soil and groundwater. Pathogens cannot be eliminated

Incineration Method:

- High labor demand. Pollutes the environment. Pathogens cannot be safely eliminated

Corpse Pool Method:

- Long processing time. Bones are difficult to degrade. Difficult to reuse

Rendering Method:

- High operational cost. Difficult site selection. Potential for secondary pollution.

Composting Fermentation Method:

- Prone to breed bacteria. Strong foul odors

Conditions for Eradicating Livestock Epidemic Pathogens

| Pathogen | Elimination Temp (°C) | Time (M) | Pathogen | Eliminating Temp (°C) | Time (M) |

|---|---|---|---|---|---|

| African Swine Fever | 60°C | 30 | Avian Influenza | 56°C | 30 |

| Foot and Mouth Disease | 56°C | 30 | Brucella | 80°C | 30 |

| Classical Swine Fever | 80°C | 2 | Mycobacterium Tuberculosis | 60°C | 30 |

| Blue Ear Disease | 56°C | 6-20 | Haemophilus Parasuis | 60°C | 5-20 |

| Porcine Circovirus | 72°C | 15-30 | Streptococcus | 60°C | 15 |

| Porcine Parvovirus | 80°C | 5 | Escherichia Coli | 65°C | 30 |

| Rabies | 56°C | 30 | Salmonella | 60°C | 15 |

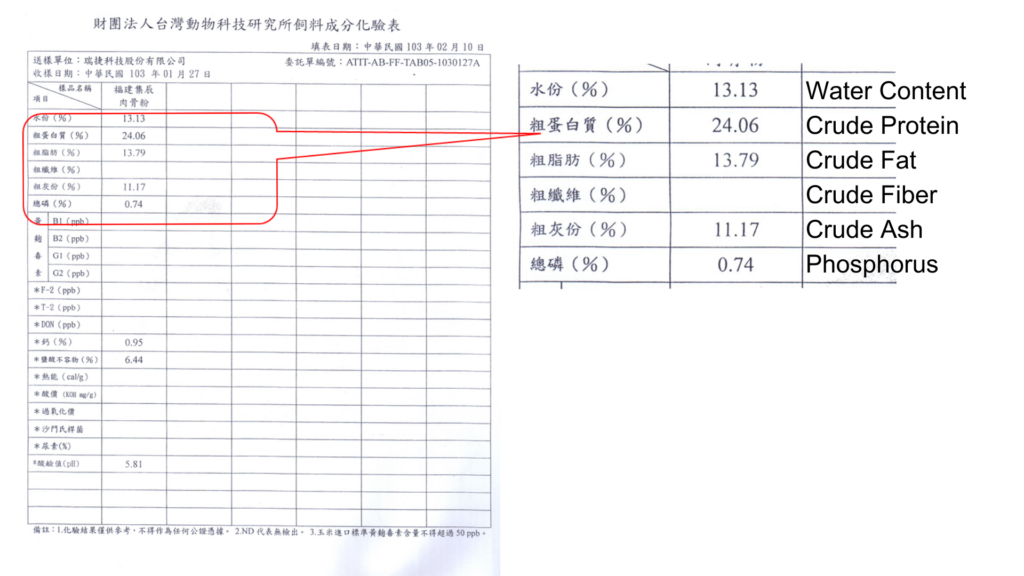

Test report of meat and bone meal processed by GDS digester with livestock waste, Greenzyme EMB-100 Plus and rice husk

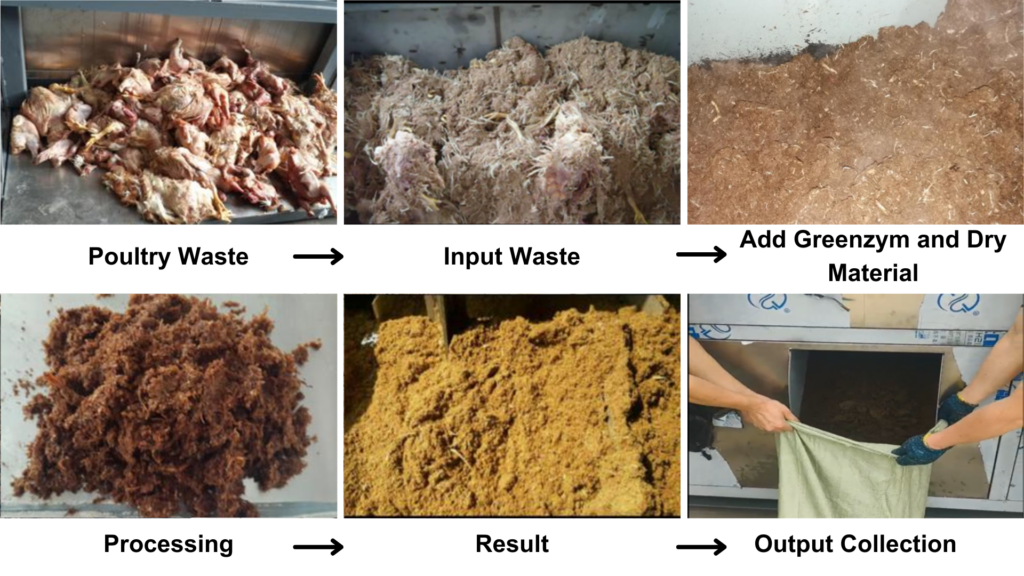

Process of Deceased Poultry Treatment

Process of Deceased Swine Treatment

| Model | GDS-200 | GDS-700 | GDS-1500 | GDS-2500 | GDS-3500 | GDS-8000 |

|---|---|---|---|---|---|---|

| Daily Capacity | 120kg | 600kg | 1300kg | 1800kg | 3000kg | 5000kg |

| Dimension | 1.5m x .9m x 1m | 2.5m x 1.2m x 1.6m | 3.5m x 1.8m x 1.8m | 4m x 1.8m x 1.8m | 5m x 2.2m x 2.1m | 5.7m x 2.3m x 2.25m |

| Operating Voltage | 220V/380V/440V | |||||

| Temp Control Range | 110C-150C | |||||

| Total Power | 13 kw | 25 kw | 30 kw | 36 kw | 50 kw | 60 kw |

| Single Batch Time | 10-20 hours (End Product Moisture Rate Below 40%) | |||||

| Motor Horse power | 2HP | 7.5HP | 10HP | 15HP | 10HP x 2 | 10HP x 2 or 15HP x 2 |

| Total Weight | 450kg | 1500kg | 3100kg | 3600kg | 5600kg | 7200kg |