About the GDM digester

Description

The Green Day GDM Digester is an advanced, fully enclosed system designed to transform livestock manure waste into high-quality organic fertilizer within just 20 hours. Utilizing state-of-the-art thermophilic enzyme technology, the GDM Digester efficiently breaks down organic waste, ensuring rapid and effective processing with fermentation.

Ease of Use

Continuous upgrades have made this digester highly functional, easy to operate, durable, and with minimal repair needs. Its streamlined installation and relocation process, along with a quick setup for running time, eliminate the need for extended monitoring. The bucket-type automatic feeding system and automatic feeding door allow one person to operate multiple units simultaneously, significantly reducing labor costs and enhancing operational efficiency.

Why Should Poultry Manure Be Fermented?

Poultry manure is rich in nutrients and organic matter, making it an excellent source of organic fertilizer. It can enhance soil nitrogen, phosphorus, potassium, and organic matter content, promoting plant growth. However, applying raw manure directly to the soil can consume oxygen, produce harmful substances like organic acids, and inhibit crop growth. Only fermented manure can be used as organic fertilizer to improve soil properties, increase organic matter content, and boost crop yield and quality.

Using untreated livestock manure can cause:

- Infectious diseases and pests

- Seedling burning

- Toxic gas hazards

- Soil oxygen deficiency (hypoxia)

- Slow fertilizer efficiency

- Environmental pollution

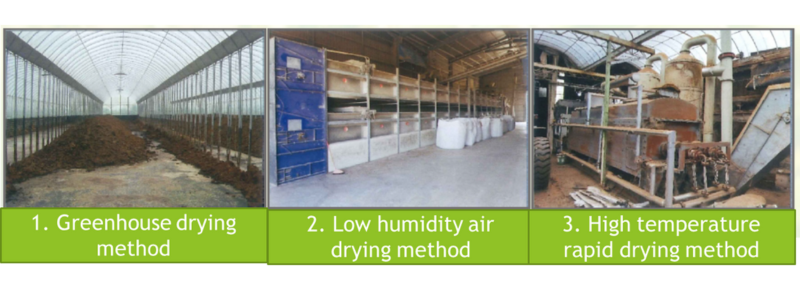

Traditional Poultry Manure Treatment Methods

Greenhouse Drying Method: Manure is spread on the ground with a thickness of 1.2 meters for sunlight drying, which takes 30-60 days.

Low Humidity Air Drying Method: This method takes 48-72 hours but has high equipment costs.

High Temperature Rapid Drying Method: This process takes 24-36 hours but requires significant manpower and energy, resulting in high operating costs.

Compost Fermentation: This method can lead to problems with flies and odors.

Effective Sterilization

For most pathogens to be killed, equipment and materials must reach temperatures above 80°C. GDM digester is designed for superior sterilization, capable of heating up to 130°C. At this setting, the material temperature rises to 90-100°C within just 3 hours, effectively eliminating pathogens and ensuring safe, sanitized output. This advanced heating capability ensures complete elimination of bacteria and viruses, prevent the spread of diseases, and reduce chicken manure moisture to less than 25%, making it a reliable solution for pathogen-free livestock manure waste processing.

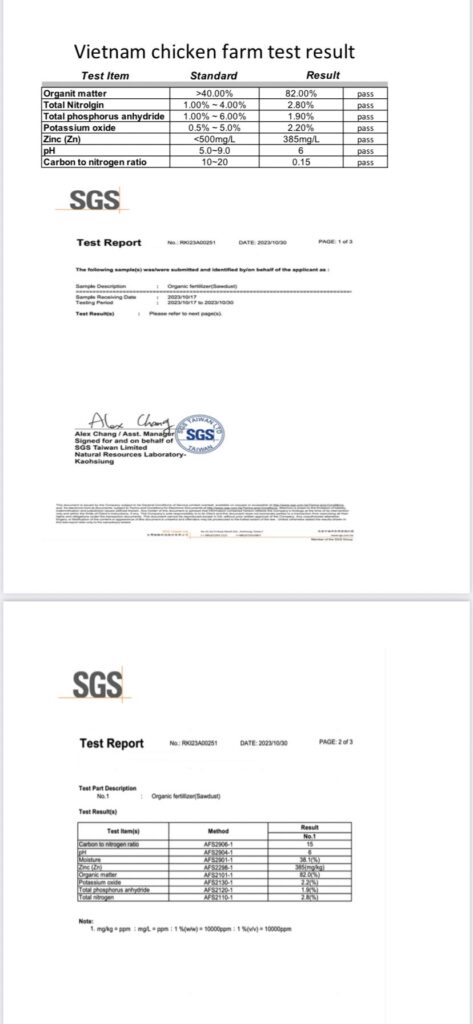

Test report of organic fertilizer processed by GDS digester with poultry manure, Greenzyme EMB-100 Plus and sawdust

Process of Livestock Manure Treatment

| Model | GDM-200 | GDM-700 | GDM-1500 | GDM-2500 | GDM-3500 | GDM-8000 |

|---|---|---|---|---|---|---|

| Daily Capacity | 120kg | 600kg | 1300kg | 1800kg | 3000kg | 5000kg |

| Dimension | 1.5m x .9m x 1m | 2.5m x 1.2m x 1.6m | 3.5m x 1.8m x 1.8m | 4m x 1.8m x 1.8m | 5m x 2.2m x 2.1m | 5.7m x 2.3m x 2.25m |

| Operating Voltage | 220V/380V/440V | |||||

| Temp Control Range | 110C-150C | |||||

| Total Power | 13 kw | 25 kw | 30 kw | 36 kw | 50 kw | 60 kw |

| Single Batch Time | 10-20 hours (End Product Moisture Rate Below 40%) | |||||

| Motor Horse power | 2HP | 7.5HP | 10HP | 15HP | 10HP x 2 | 10HP x 2 or 15HP x 2 |

| Total Weight | 450kg | 1500kg | 3100kg | 3600kg | 5600kg | 7200kg |